Our technology

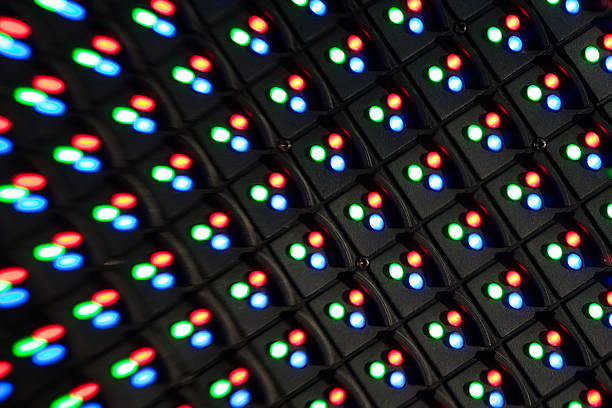

Displays based on inorganic micron-size light emitting diodes (mLEDs) are expected to disrupt the organic LED based display technology which began to dominate the display products today. Micro-LED displays employ arrays of microscopic LEDs (3 to 10 micrometer wide) to comprise their individual pixel elements. Compared to others, mLED displays can deliver superior contrast, faster response times, higher reliability, and considerably reduced energy consumption.

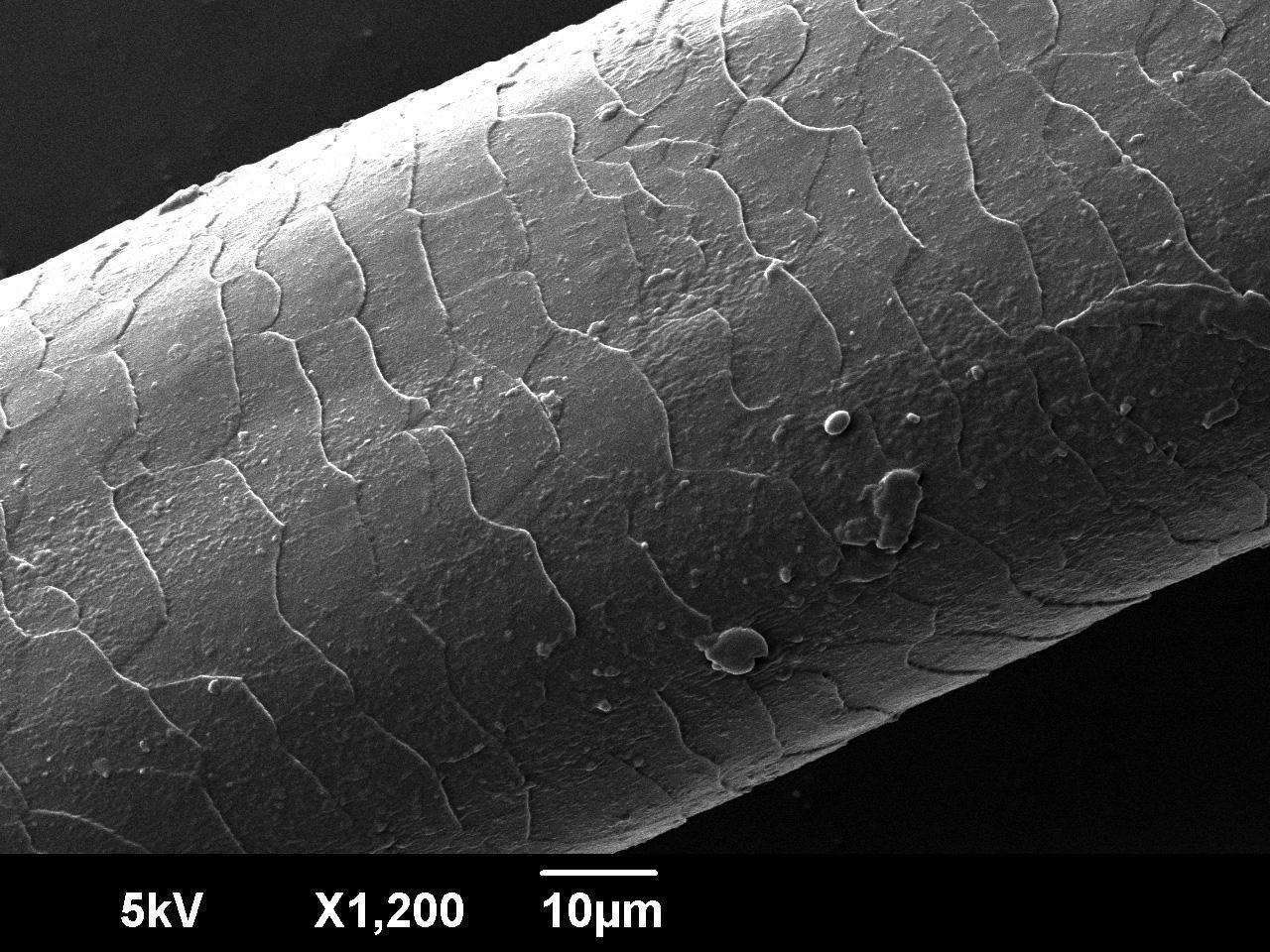

For reference, the human hair is about 100 micrometers thick.

The most devloped approach to the fabrication of mLED displays requires transferring mLEDs (emitting the three basic colors Red, Blue & Green) from three different native substrates (on which they were fabricated) to a display panel. Since these mLEDs are in the few micrometer size range, the task of selectively transferring a plurality of these devices is challenging.

Leveraging LuxNour Founder’s extensive experience in advanced semiconductors process technology development and high volume production, we were motivated to develop a production-worthy equipment technology and process flow to enable the mLEDs display industry.

The Challenge

How to transfer a massive number of micron-size objects, placed on a given layout grid, to another substrate with a different layout?

Not only that , but we also need to perform that transfer under high volume production constraints, where tolerance to normal production variations and compliance with process control requirements are fundamental. In general, LuxNour’s transfer technology can be utilized for applications requiring the transfer of large number of micron-size objects.

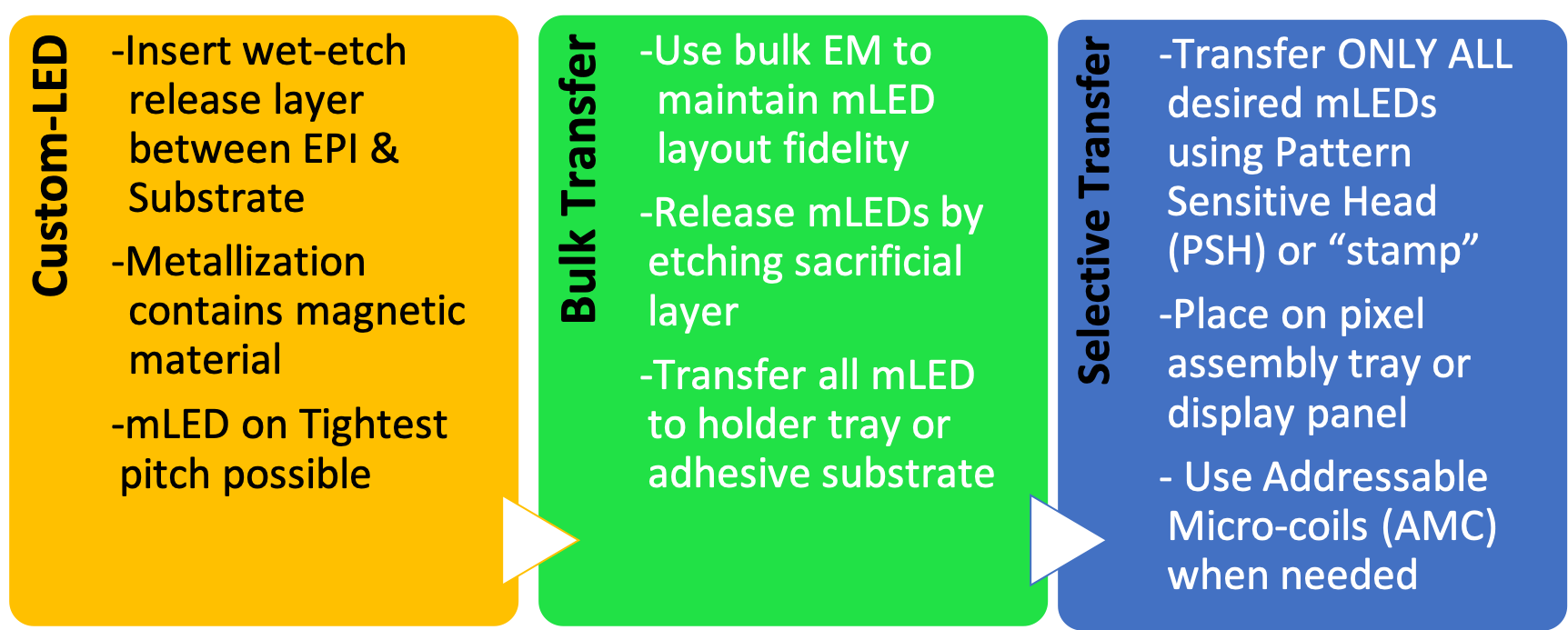

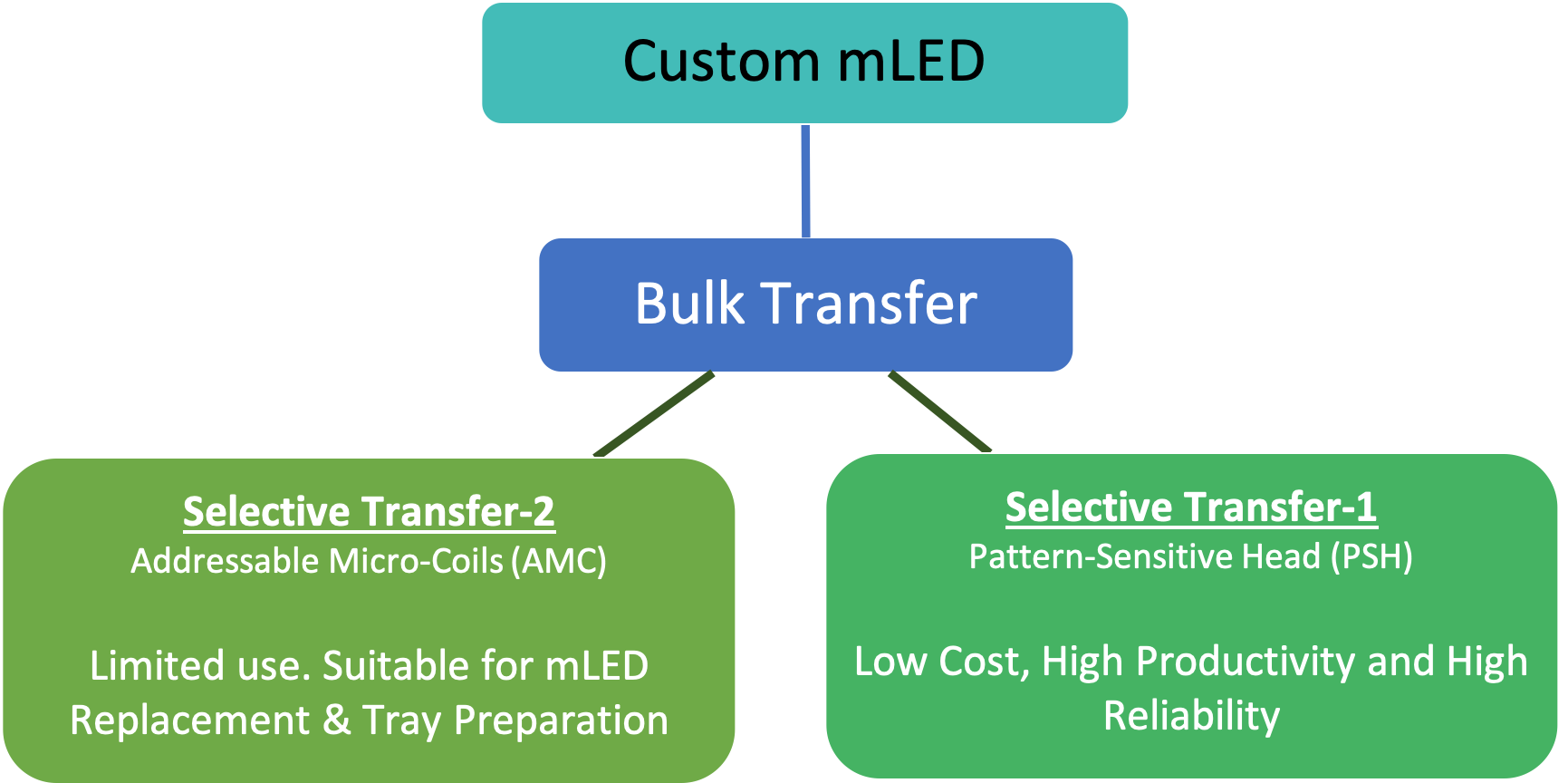

Elements of LuxNour’s Micro-Transfer Process

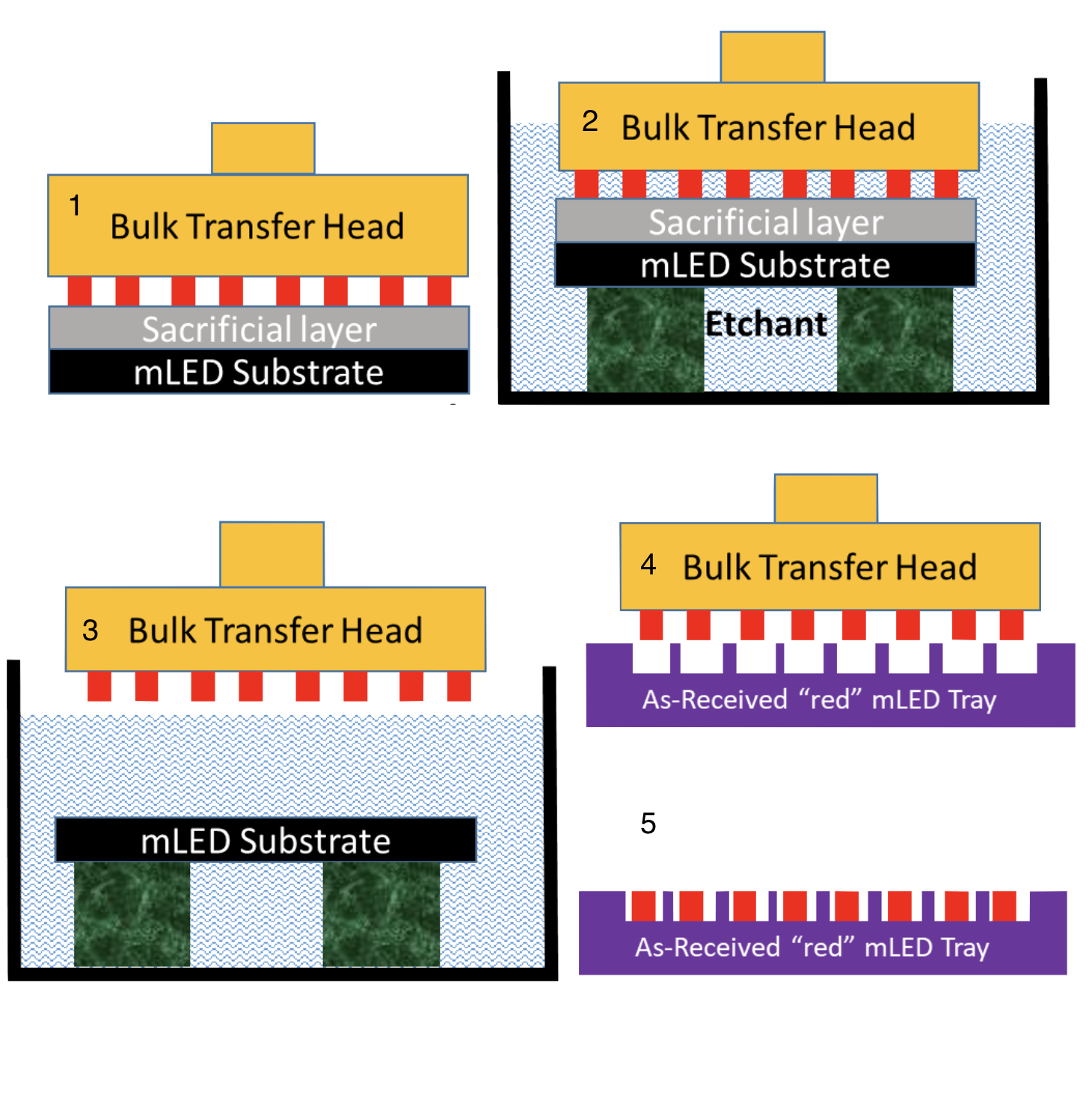

Bulk Transfer

Objective:

Release mLEDS from native substrate

Transfer ALL just released mLEDs to tray substrate.

Method: Utilize wet etch to release mLEDs from the native substrate while being held by a “bulk electromagnet”. The bulk electromagnet faithfully maintains the spatial layout distribution of the released mLEDs as that on the native substrate.

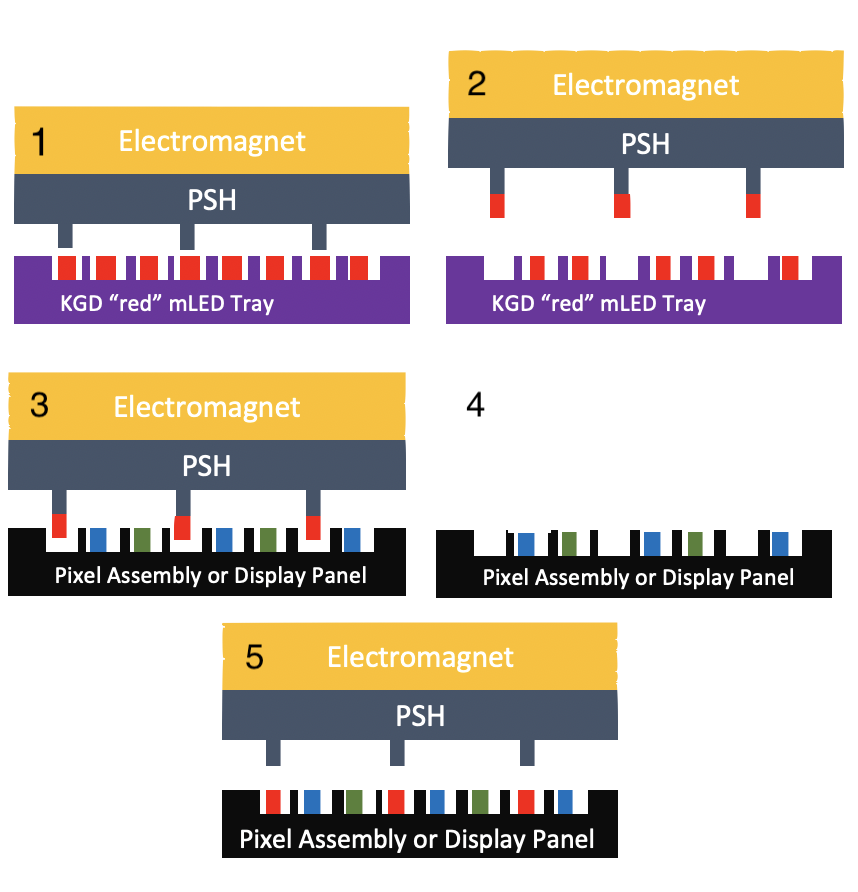

Pattern-Sensitive Transfer

Objective:

Transfer ALL desired mLEDs from a Known-Good-Die (KGD) tray onto a pixel assembly tray or display panel.

Method:

1. High Productivity: Utilize LuxNour’s Pattern Sensitive Head (PSH).

2. For limited purpose transfer, not limited to a specific layout constraint, use LuxNour’s Addressable Micro-Coils (AMC) head.

Pattern Sensitive Head (PSH)

Objective:

Transfer ALL desired mLEDs from a Known-Good-Die (KGD) tray onto a pixel assembly tray or display panel.

Method:

1. High Productivity: Utilize LuxNour’s Pattern Sensitive Head (PSH).

2. For limited purpose transfer, not limited to a specific layout constraint, use LuxNour’s Addressable Micro-Coils (AMC) head.

Applications

Our initial focus is on the two following applications:

1. Enabling mLED-based Displays: LuxNour enables the broad use of inorganic micron-size Light Emitting Diodes (mLED) in displays by providing the ecosystem a much needed production-worthy massive parallel transfer equipment for the mLED.

2. In Advanced Packing: LuxNour’s ability to selectively transfer large plurality of small to micro-size devices may provide the semiconductor packaging industry with a more productive, efficient and reliable die transfer technology.